Contract manufacturing for the orthodontic and dental industry

CDB CORP

2304 MERCANTILE DRIVE

LELAND, NC 28451

910.383.6464

serVice

When you work with CDB, you are not just a customer, you become a partner. Like any good partner, you should expect us to have just as much passion and enthusiasm about your project as you do. You can also expect world class service and expertise. Once we begin working together, our engineers will begin with the most important step in the development process…listening. Whether you have a concept or completed design, we take great pride in our ability to ascertain exactly what your needs and specifications are. What you will also receive is expert advice.

From concept to commercialization the CDB team will assure you that your design is the best it can be or advise on ways to make it even better. Service doesn’t end with design, as a partner we continue to work with you through every facet of development and commercialization all the way to packaging, assembly, forecasting and on demand marketing assistance. Our goal is to work together to maximize your sales potential and make you shine!

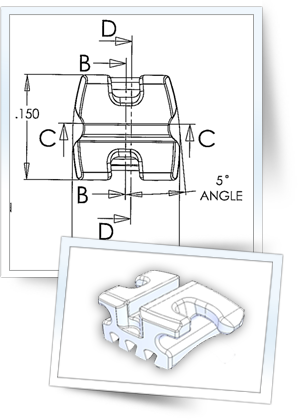

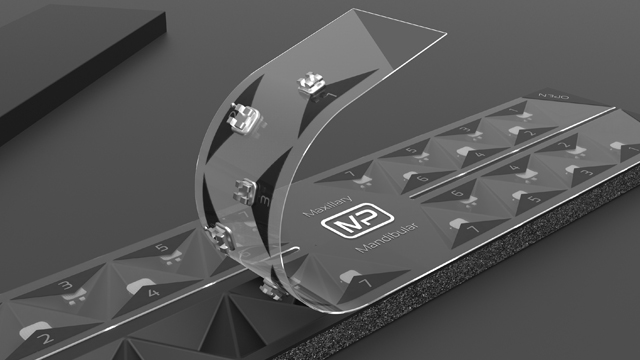

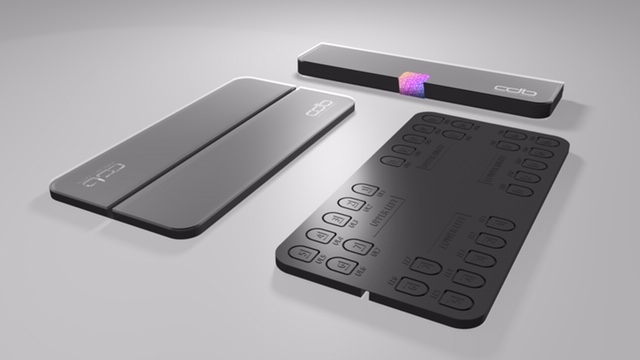

Design Engineering

At the heart of every project lies one simple, but incredibly important philosophy and that is, “timing is everything.” When we combine our 20 years of world-class ceramic manufacturing and engineering with the sophistication of SolidWorks 3D Cad solutions, your concept will become a reality. We relish the challenge of working with a design only thought to exist as a stainless product and bring it to reality in aesthetics, both ceramic and composite. After carefully listening to your needs and reviewing your design schematics, we will create a virtual three-dimensional mock-up. This important stage is where we will determine potential challenges a particular design may encounter. This determination is based on years of experience and industry expertise considering the needs of all beginning with the distributor to the doctor and ultimately the patient.

Prior to commercialization and perhaps the most important stage of the development process is utilizing CDB’s proprietary prototyping capabilities. Our engineering team has the ability to quickly and cost effectively fabricate working prototypes for review and testing. With this process, we can produce a full set of working brackets from CAD drawings within weeks.

Whether you need ceramic duplication of a stainless line or the latest innovation in bracket design, with CDB you save time and money. You can move forward with any product line knowing that your brand is being represented with the highest quality possible.

Contract Manufacturing

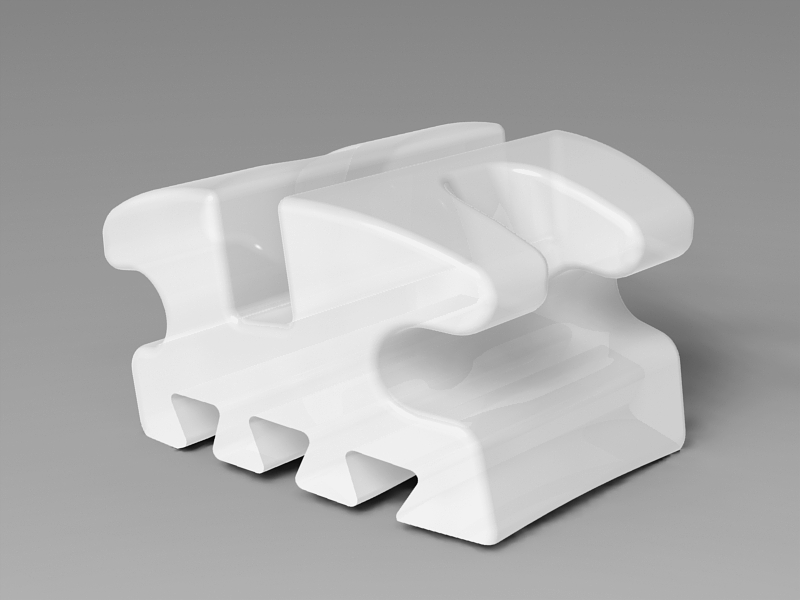

Advanced Ceramic Manufacturing

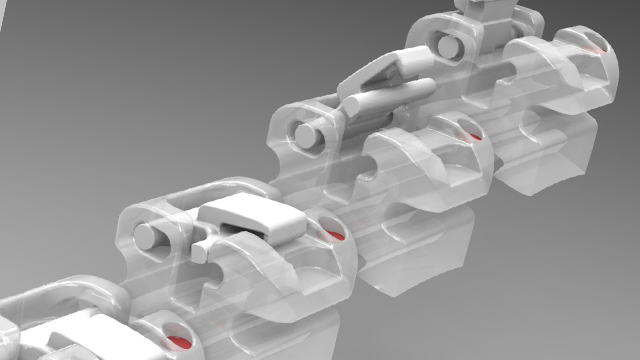

Capacity and advanced ceramic expertise are what keep CDB at the forefront delivering exceptional value for all CDB ceramic products. Whether you looking for complex precision components or speed to market is a necessity, CDB’s has the manufacturing abilities to satisfy your demand.

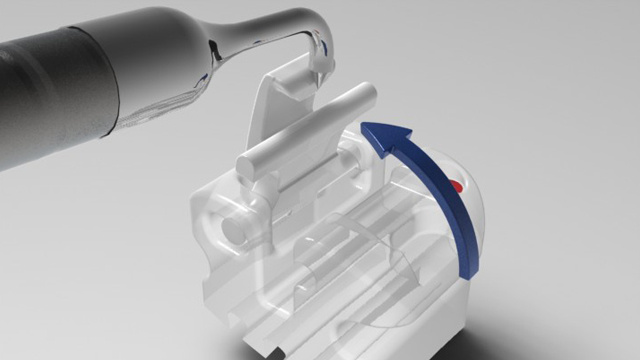

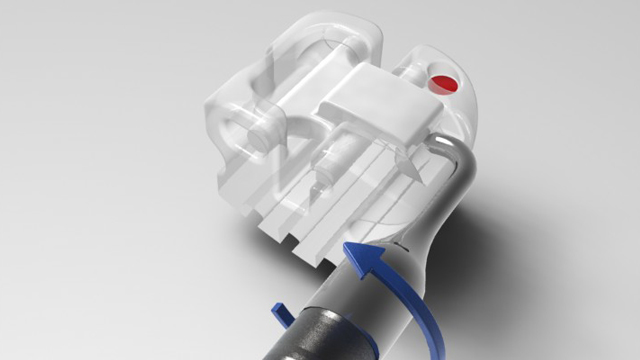

Our highly sophisticated ceramic injection molding (CIM) technology make it technically feasible to produce medium to large volumes of complex, ultra-high precision ceramic components. This technology brings intricate geometries and complex product designs together with superior performance characteristics of ceramic.

When rapid development and commercialization are a priority, CDB’s critical manufacturing techniques combined with proprietary machining processes offer, customizable product solutions in just a few months.

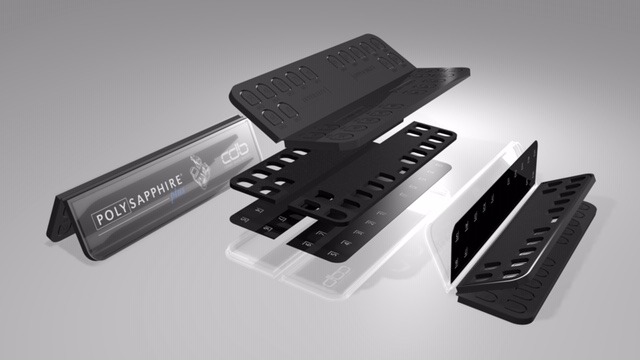

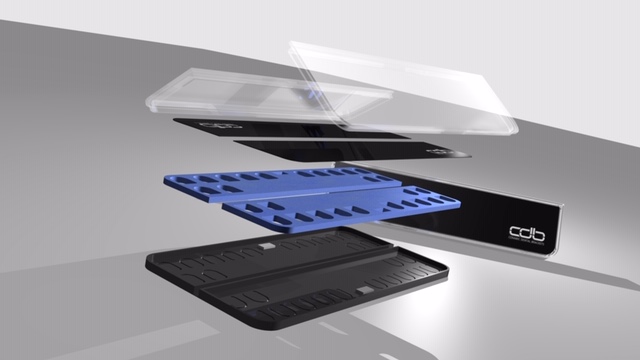

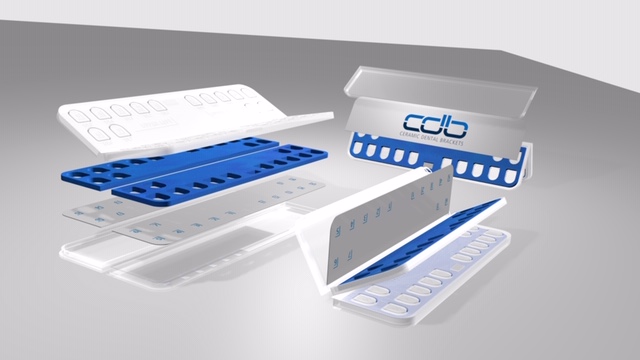

High-tech Composite Resin Manufacturing

Advanced formulas and materials bring new choices in composite manufacturing. Innovative design features and specialized product attribute possibilities are virtually endless. Various composite materials offer options in both ultra-clear and tooth colored to satisfy any aesthetic need.

With no exception, all of us at CDB are committed to preserving our legacy and long-term commitment to keep you smiling. It would be our pleasure to support your business with our in-house expertise, advanced technology and years of experience delivering quality aesthetic appliances exclusively made for you.

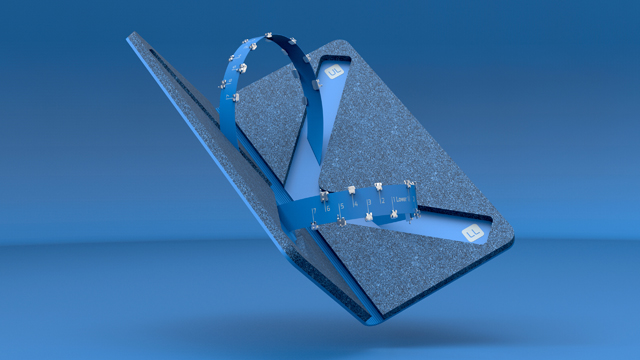

Packaging / Assembly

CDB offers you unparalleled flexibility with your packaging options. We have the capabilities to customize labels and packages the way you need them and completely support your branding style. Whether you need packs of five or ten, individual patient kits or bulk, our packaging team is equipped to meet your needs and comply to your standards.

Working with CDB means you have a partner who will provide everything you need, every step of the way. When the brackets are ready for distribution, there will be no question that what is being delivered are aesthetic brackets of the highest quality, under your brand, and your packaging. That is the CDB promise.

Product development

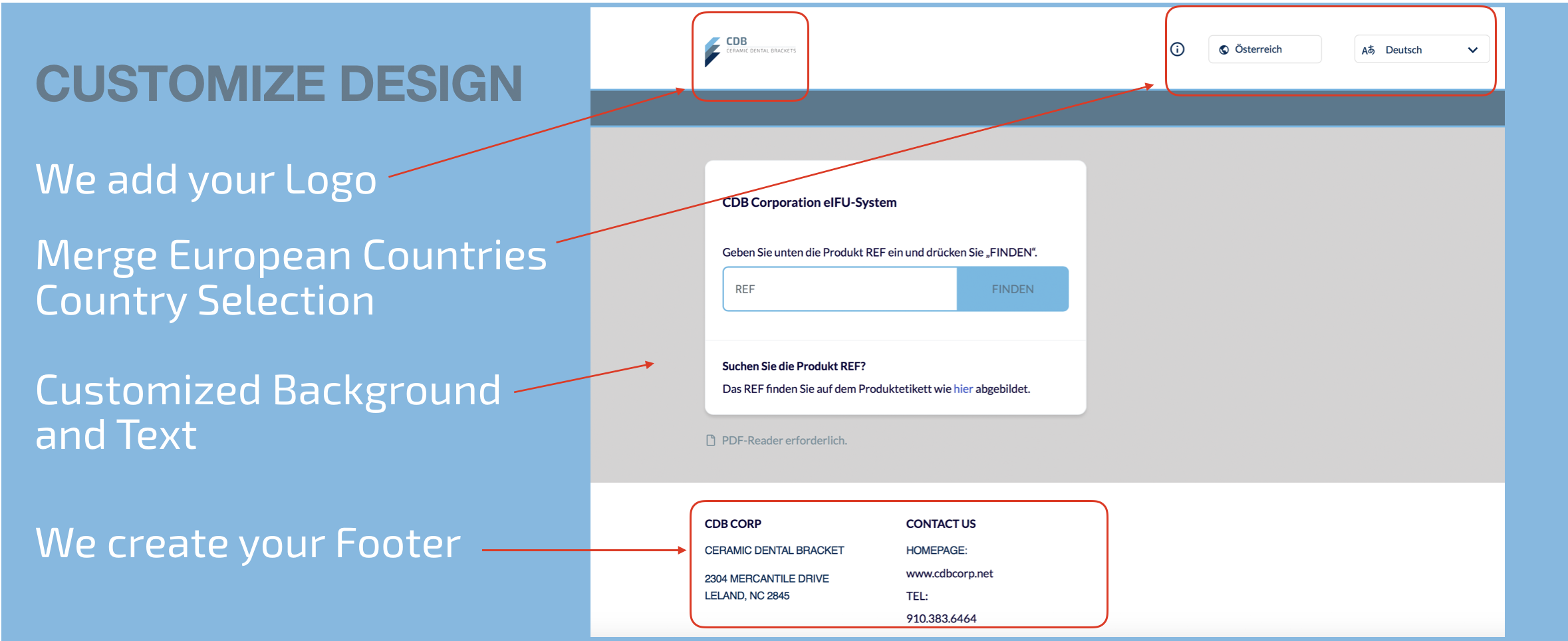

eifu service

Our Service

- Login to manage

- Setup a signing key

- Create a product line

- Add a product

- Add a content

- Add a document

- Publish everything

- View on Connect

If the medical devices allow it, the instructions for use can be provided to the user other than in printed form:

– faster and simpler processes

– more flexibility (languages, markets, product launches)

– environmental benefits

CDB Corporation

2304 Mercantile Drive

Leland, NC 28451

Phone: 910.383.6464

Fax: 888.280.1556

orders@cdbcorp.net